DK2+ Motion System

DK2+ Motion System

USA domestic shipping is 3-5 days. All international shipping is typically 5-7 days.

Double the performance at half the cost of other turnkey motion systems. Utilizing modern controllers with low total loop latency with no distracting effects or gimmicks.

Similar to our DK2 motion system, the DK2+ is a pure motion system for serious sim-racing enthusiasts, drivers, researchers and sim centers. The system shares the same design and construction as our industrial-grade DK-X motion systems used in our full motion vehicle and platform simulators. All our systems are mechanically and electrically engineered around our unique motion algorithms to provide the most realistic and pure representation of vehicle dynamics without relying on pre-recorded canned effects.

DK2+ takes a modern approach to signal processing and motion control to create the most responsive system on the market. Every elevation change, vehicle movement, surface change and gear shift, is captured and reproduced within 2” (50mm) of the available mechanical stroke. (Full Send Video Proof)

The DK2+ was originally created to serve many sim centers around the world. The larger motor is capable of 800 lbs. (360 kg.) of total supported mass and hence can support a larger variety of drivers or exceptionally heavy rigs. The DK2+ continues to be the go to motion solution for sim centers or for professional users looking for that little bit more.

- mono-block, machined billet actuators with 2” (50 mm) travel

- powerful, responsive and compact American Teknic servo motors

- maximum weight capacity (chassis and driver):

- billet-machined floating feet with large rubber pads

- aluminum t-slot mounting hardware compatible with 25 to 45 series profiles

- single controller box (115v/240V compatible) with power and network cables

- two sets of 1m and 2m data and power cables from the controller to actuators

- Sigma’s motion algorithms & simulation software

- automatic Over-the-Air controller firmware updates

- PC side (Windows 10)

- Controller side (Real-time OS in ARM)

- Controller side (2 low-latency micro-controllers)

- Electrical connection from 2nd micro-controller to ClearPath motor

- ClearPath servo motor

Clear Path Integrated Servo Motor CPM-SDSK-3432P-RLN

- Rated (RMS) Torque = 209 oz-in (1.5 N-m)

- Peak Torque = 698 oz-in (4.9 N-m)

- Max Speed = 2,380 rpm

- Total Weight Capacity (for optimal performance), including fully-loaded simulator with driver:

- Optically isolated, current-based I/O system (EMI free)

- Average system draw at 110V is about 0.330 KW (Peak 1600VA)

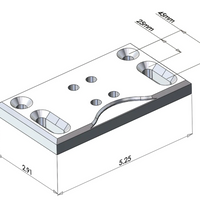

In-house manufactured actuators | 3D Model: Available Upon Request

- 2” (50mm) actuator travel

- speeds of 7.93"/s @ 2,380 rpm

- 5/8” diameter, USA ball screw and nut

- 2” (50mm) diameter piston

- Mono-block machined billet aluminum body

- All American made components

Motion Controller | 3D Model: Available Upon Request

- ClearPath IPC-5 Intelligent Power Supply

- Input voltage 95-125/190-250 VAC; 50-60Hz (NO INVERTERS REQUIRED!)

- Real-time and remote motion control via default browser or phone/tablet

- Signal processor with amplifier

- Embedded microcontrollers

- Shielded Molex connectors

- 15" wide, 9.25" deep and 3" tall

Sigma's Software and Algorithms

- Motion Integrity™ architecture to provide ultra-responsive, precise and accurate motion control

- Dynamic scaling algorithm to best represent all layers in the available actuator travel

- Organic and natural feeling Velocity Trap™ algorithm

- Smooth integration of the 10 motion layers

- Real-time remote control interface

- Custom Motion Profiles

Mounting hardware

- Machined billet mounting bracket

- T-slot aluminum extrusion (80/20) friendly

- Machined billet floating feet with mounting capability

We ship from Huntington, CA. Orders placed before 11am PST will ship the same day, while orders placed after 11am will ship the next business day.

Unique Features of all DK Systems

- American made motion system with premium support and components.

- Billet aluminum and steel design for incredible strength and haptic feedback.

- Nickel plated solid steel pistons for ultimate strength, quiet operation and durability.

- Industry only 75 VDC power architecture with custom cable length options.

- American made Teknic motors tuned and tested to work with our DK actuators.

- Advanced motion algorithms controlling speed, acceleration and jerk in real-time.

- Any DK motion system combination can be upgraded at anytime into the future.

- Software only gets better over time with continual over-the-air software updates.

Sigma DK2+ Motions Systems feature

All DK motion systems are made in the USA from a solid piece aluminum for optimal strength, durability and the best haptic feedback translation. Machining from billet aluminum is significantly stronger over other methods of production such as casting, bolted assemblies or 3D printing. Each system also features a solid 2” OD steel piston and oversized ball screws for optimal smooth performance and long service life with no maintenance required. The DK system installs in less than 30 minutes to almost any aluminum extrusion with our own billet aluminum brackets and components.

Motion Specific Electrical System

Sigma uses premium American-made Teknic integrated motors specifically tuned to run Sigma’s advanced motion algorithms. At double the price of conventional motors, the servos have three times the performance of conventional motors. We are also the only company to feature 75VDC electrical architecture for various performance standards. Each motor is optically isolated guaranteeing zero electrical or magnetic interference. Cable lengths from the controller to the motors can go up to 150-feet and the controller connects via an ethernet cable to the computer for optimal signal integrity. The controller is switchable between 120/240v and ships with power cables and accessories specific to your region.

Specialized Motion Software

Sigma takes a first principles approach with our motion software and algorithms. We design, build and develop all our embedded and motion software in-house. This allows us to achieve absolute control of our simulation specific control of its mechanical and electrical integration. Our software features specialized motion layers and unique algorithms to achieve what we call Motion Integrity or the most accurate representation of simulated motion. Pitch, roll, heave, environment, and our True Haptic engine and road vibrations are some of the best in the industry. Our software also installs quickly and has automatic over-the-air software and firmware updates. Remote tuning and control of the system is convenient and can be done in real-time with a secondary device without having to stop and exit simulation software.

Pure Algorithms no Effects or Gimmicks

Velocity Trap Algorithm

Our base motion algorithm is unique to Sigma and provides a smooth and natural motion representation. Available to all

DK motion systems.

Dynamic Scaling Algorithm

This algorithm allows for the full use of the actuators available stroke. Allowing all of the motion layers to be intelligently represented at all times.

True Haptics Algorithm

Our first principles approach to high frequency vibrations with no canned effects. Focusing on pure signal which results in less tunning and more driving.